Submitted by Administrator on Thu, 09/12/2010 - 11:30

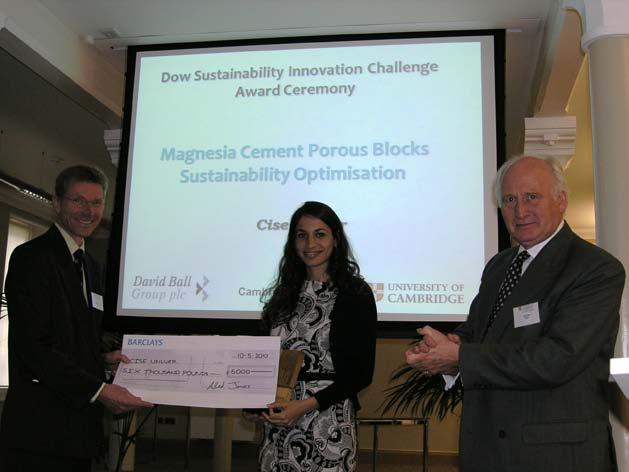

Cise Unluer wins Dow Sustainability Student Award 2010

Cise Unluer, a second year PhD student in the Geotechnical and Environmental Research Group, has won the Cambridge University 2010 Dow Sustainability Innovation Student Challenge Award. The competition is organised by the Cambridge Programme for Sustainability Leadership for Dow, a company that connects chemistry and innovation together with the principles of sustainability to help address many of the world's most challenging problems.

The Challenge recognises and rewards Students and Universities for their innovation and research of sustainable solutions to the world’s most pressing social, economic and environmental problems. Dow established the award to encourage and promote forward thinking in social and environmental responsibility and acknowledges the energy, commitment and enthusiasm of the students and their university professors, sponsors and facilitators who support their efforts of sustainable innovation and continued excellence.

Cise’s work focuses on the sustainability optimisation of reactive magnesia cement porous blocks. Portland cement (PC), the most widely used construction material in the world with global production of over 2.5 billion tonnes/year, is responsible for 5-7% of global anthropogenic CO2 emissions. As a result, one of the three major sustainability initiatives in the cement industry is the development of alternative more sustainable cements.

Reactive magnesia cements have emerged as such an alternative. They are manufactured at much lower temperatures and work by capturing significant quantities of CO2 leading to significant strength gain. They are also potentially completely recyclable, can utilise significant quantities of wastes and are also expected to have excellent thermal properties and durability performance. Cise’s work is investigating the contribution that changes in the cement and aggregates components as well as inclusion of additives and admixtures and varying curing conditions have on optimising the sustainability together with enhancing the technical performance of the blocks.

2 emissions. As a result, one of the three major sustainability initiatives in the cement industry is the development of alternative more sustainable cements.

Reactive magnesia cements have emerged as such an alternative. They are manufactured at much lower temperatures and work by capturing significant quantities of CO2 leading to significant strength gain. They are also potentially completely recyclable, can utilise significant quantities of wastes and are also expected to have excellent thermal properties and durability performance. Cise’s work is investigating the contribution that changes in the cement and aggregates components as well as inclusion of additives and admixtures and varying curing conditions have on optimising the sustainability together with enhancing the technical performance of the blocks.

2 leading to significant strength gain. They are also potentially completely recyclable, can utilise significant quantities of wastes and are also expected to have excellent thermal properties and durability performance. Cise’s work is investigating the contribution that changes in the cement and aggregates components as well as inclusion of additives and admixtures and varying curing conditions have on optimising the sustainability together with enhancing the technical performance of the blocks.